Training Room 1

| Site: | MoodleHUB.ca 🍁 |

| Course: | HCS3010: Workplace Safety Practices copy 1 |

| Book: | Training Room 1 |

| Printed by: | Guest user |

| Date: | Sunday, 14 December 2025, 11:31 PM |

Description

Created by IMSreader

1. Training Room 1

Training Room 1: Defining Workplace Safety Principles and Practices

Introduction

Training Room 1 is all about workplace hazards: recognizing hazards and putting controls in place to minimize the risk.

You may already have some understanding about safety at work, or workplace safety may be new for you. Either way, use these key questions to guide you as you explore this training room:

- What is safety at work?

- What does it mean for you, as a worker, to put safety into practice?

Now is a good time to review Course Checklist and to take a look at Training Room 1 Project. It is important that you know what you will need to do for the Project so that you can collect information as you work through Training Room 1.

There are some terms used in workplace safety that you need to be familiar with. These terms are accident, incident, and causation. Definitions for these terms are available in Glossary Terms. You can access Glossary Terms in the Toolkit at any time or by clicking the Glossary icon at the top of the page.

What definitions of accident and incident can you find? You might want to ask friends, family, and co-workers; search the Internet; or use a dictionary to come up with your own understanding of the difference between accident and incident.

You might also want to read a debate about these terms in SafetyXchange, an online community for safety professionals. First, read the original blog post at SafetyXchange: “Accident Is the Proper Terminology.” Then read the discussion that followed at SafetyXchange: “Accident vs. Incident.”

Consider also the definition of causation, often called the root cause. Check out the information on causation given by the Canadian Centre for Occupational Health and Safety (CCOHS) on its “Accident Investigation” webpage.

![]()

With a friend, family member, or classmate, share your understanding of accident, incident, and causation. Discuss the following questions:

- What is an accident?

- What is an incident?

- Why look for causation?

- What are some common root causes?

1.1. Page 2

Training Room 1: Defining Workplace Safety Principles and Practices

Safety Principles and Practices

Recall from HCS3000: Workplace Safety Systems, that the purpose of a health and safety management system is to identify, assess, and control workplace hazards. To be effective, the following components are essential:

- analysis of health and safety hazards at the work site

- control measures to eliminate or reduce risks from hazards

- clearly stated company policy and management commitment

- worker competency and training

- an inspection program

- emergency response planning

- incident investigation

- program administration

This training room will focus specifically on the first two points: hazard assessment and control measures used on the job site.

Types of Hazards

There are five major categories of hazards. You learned about these in HCS3000.You will need to know what these hazards are in order to complete the rest of the training room and the Training Room 1 Project. To review these five hazard categories, watch “Identifying Hazards.”

1.2. Page 3

Training Room 1: Defining Workplace Safety Principles and Practices

You have reviewed the main parts of a health and safety management system and the main hazards found in the workplace. It is time to learn about three types (and one sub-type) of controls used to elliminate or reduce the risks from workplace hazards.

Recall from HCS3000 that the best hazard control is to remove the hazard from the workplace. When this is not possible, there are three levels of control to consider to reduce risks: engineering controls, administrative controls (including WHMIS), and personal protective equipment.

Engineering Controls

Engineering is the preferred method of control. Engineering for safety is all about good design. Your first thought may be that engineering control is about the design of safe machinery and tools. This is certainly a big part of engineering, but there is more. Engineering also includes the design of processes and practices to eliminate or reduce hazards.

Open “Hazard Assessment and Control” to find out about engineering controls that are used on job sites. After clicking “Forward,” select “Module 3: Types of Controls,” and then select “Engineering Controls” from the quick index.

Administrative Controls

Administrative controls are the next approach when engineering controls do not sufficiently reduce risks from a hazard.

To learn about the ways that administrative controls may protect you on the job site, open “Hazard Assessment and Control” again. This time, Select “Module 3: Types of Controls,” and then select “Administrative Controls” from the quick index.

1.3. Page 4

Training Room 1: Defining Workplace Safety Principles and Practices

Introducing WHMIS

WHMIS is an important part of administrative controls for chemical hazards at your job site. Sounds like just a whole bunch of letters? WHMIS is more than just a fancy name. WHMIS may become a regular part of your work life. If you have not already taken a WHMIS course as part of a job, you will probably run into WHMIS through your work experience at some point.

Why do you need to know about WHMIS? Watch “Why WHMIS?” for two simple reasons.

For now, you need to understand only the basics of WHMIS. You will learn more about WHMIS in Training Room 2 as you explore chemical safety practices in more detail.

George Doyle/Stockbyte/Thinkstock

Go get your favorite cereal from the cupboard. Look at the box.

- Can you name the brand?

- Can you find information on where the company is located?

- Is there a list of ingredients?

- Can you find other important information, such as nutrition facts or serving suggestions?

The point of this investigation wasn't to get to know your cereal; rather, the investigation was about the importance of getting information on products. Some products in the workplace can be harmful to you, and that’s where WHMIS comes in.

WHMIS stands for Workplace Hazardous Materials Information System and is a Canadian hazard-information system. WHMIS was established to

- help workers identify hazardous materials

- help workers use these materials in a safe manner

WHMIS has three main parts:

- labels

- Material Safety Data Sheets (MSDS)

- worker education

Learn more about these parts by watching “Making WHMIS Work”. This is only the first six minutes of the video. You will watch the rest of the video in Training Room 2.

Explore the three main parts of WHMIS in “WHMIS at Work.” Read through sections 2, 3, and 4 to find out about labels, MSDS, and worker education.

![]()

Check your understanding of the three main parts of WHMIS by looking at this “WHMIS at Work” diagram. With a classmate, discuss how each of the parts of WHMIS come together to keep you, the worker, safe around chemical hazardous.

1.4. Page 5

Training Room 1: Defining Workplace Safety Principles and Practices

George Doyle/Stockbyte/Thinkstock

You have learned about two types of controls used in the workplace: engineering and administrative controls. You also learned about WHMIS, an administrative control. This section covers the last line of control: personal protective equipment. By law, your employer must make sure that you, the worker, is trained in the “correct use, care, limitations and assigned maintenance of the personal protective equipment.” (© Government of Alberta, Occupational Health and Safety Code)

Personal Protective Equipment

Sometimes no amount of personal protective equipment would save the day. Want proof and a laugh? Search the Internet with these key words: “funny sport bloopers.” You might share what you find with your classmates.

Does wearing a seatbelt allow you to drive at 150 km/hr. while texting and be safe? Of course not. A seatbelt will contribute to your safety, but you still have to drive sensibly. It is the same with personal protective equipment (PPE). Wearing a hard hat, a respirator, goggles, or any other piece of PPE does not guarantee your safety. You still have to make the right decisions and work safely.

PPE is the last control measure used after everything else has been tried to reduce or eliminate hazards. PPE includes such things as hard hats, gloves, goggles, shields, glasses, aprons, coveralls, leggings, respirators, and fall protection. Wearing PPE reduces the chance of getting injured.

Watch Introduction to Personal Protective Equipment to find out how PPE can help protect you.

See if you can figure out which type of PPE protects which part of the body in Matching Game: Personal Protective Equipment.

1.5. Page 6

Training Room 1: Defining Workplace Safety Principles and Practices

Check your understanding by completing “Hazard Assessment and Control: Check Your Understanding.” After selecting “Forward” to continue, select “Check Your Understanding” from the main menu.

Steps in Field-Level Hazard Assessment

Congratulations! You are armed with knowledge about the principles of workplace safety. You know the types of hazards that may be on the job site and the controls your workplace uses to reduce the risks. Now, how do you put this knowledge to use in your workplace?

Work through “Recognizing Workplace Hazards: See it Again for the First Time” to learn about the five steps you can use to put safety principles into practice. From the main menu, select “Introduction to Workplace Hazards.” When you have worked your way through the first part of this section, you will begin the section called “Steps in Field Level Hazard Assessment,” which starts on page 13 of the interactive.

1.6. Page 7

Training Room 1: Defining Workplace Safety Principles and Practices

Training Room 1 Summary

You have reviewed the principles of a workplace health and safety management sytem and the main hazards found on the job. You have added to your knowledge the three types of controls used to reduce the risk of injury from hazards in the workplace. These controls were

- engineering controls

- administrative controls (including WHMIS)

- personal protective equipment

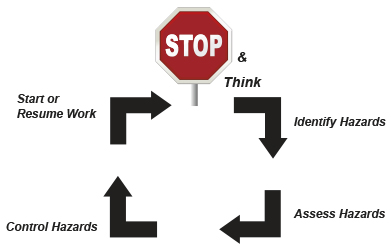

Finally, you learned the five steps to take as a worker to put this knowledge into practice:

- Stop and think.

- Identify hazards.

- Assess hazards.

- Control hazards.

- Start or resume work.

You are now ready to complete Training Room 1 Project.

1.7. Project

Training Room 1: Defining Workplace Safety Principles and Practices

Project

You will create a presentation that showcases your knowledge of the safety controls for each of the five types of workplace hazards. The three levels of hazard controls and the five steps in field-level hazard assessment are examples of the kind of information you will include in your presentation.

Your presentation can take any form that you and your teacher agree upon. For example, you might present your information as a combination of text and pictures, a computer presentation, a graphic design, or a video. Whatever format you choose, ensure that your presentation includes all required information and references.

Training Room 1 Project Example shows just one way to showcase your knowledge in the form of a PowerPoint presentation. Notice how the slideshow incorporates the three levels of hazard controls that you have studied. In your presentation, remember to address each of the five types of workplace hazards.

Preparation

What Is Required?

You will need the supplies and/or software necessary to create your presentation.

What Do I Need to Do?

Your presentation must address the following questions:

- What are workplace health and safety principles?

- What does it mean to put these principles into practice as a worker?

- What controls are put into place for each of the five main hazard types?

- What does it mean to put these controls into practice for each of the five main hazard types?

In your presentation, you must

- describe each of the five main hazard types

- provide three examples for each of the five hazard types

- identify the controls used in each of your examples

How Do I Do It?

- Complete Training Room 1: Defining Workplace Safety Principles and Practices.

- As you work, take notes to help you complete your presentation. For example, gather examples of workplace hazards as you come across them; you might even have examples from your own experience. If you are listing PPE as a control used in an example, list what kind of PPE was used. If WHMIS was used, give specific examples of what practices were used, such as the label used. You will need to do some research beyond the course to fully address the questions. Organize all of your information using the Safety Practices Planner.

- Create your presentation using text and pictures to reveal your knowledge of the safety principles and practices that exist to keep you safe on the jobsite.

What Do I Already Know?

From your previous studies in HCS3000: Workplace Safety Systems, you know how to define workplace safety and wellness. You know the essential components of a health and safety manangement system.

Assessment

Summative Assessment (Project)

When marking project assignments, your teacher will consider the extent to which you do the following:

- Follow the directions given for the project.

- Collect, analyze, and interpret information appropriately with supporting details.

- Organize information in an appropriate way that allows information to be easily located and read.

- Communicate ideas clearly and correctly, including citing references.

- Present your ideas in a clear and appealing format, using appropriate supporting information.

Your teacher will assess your work using the Training Room 1 Project Rubric.

Formative Self-Assessment (Reflection)

Respond to the Formative Self-Assessment Reflection Questions once you have completed the project.

![]() Remember to save all of your work in your course folder.

Remember to save all of your work in your course folder.

Project Summary

Once you have completed this project, submit your completed Formative Self-Assessment Reflection Questions and your presentation to your teacher.

Your teacher may ask you to present your reflection and presentation.

Next Steps

Congratulations! You have completed Training Room 1. You now have some tools for keeping safe on the job. In Training Room 1 Project, you showed your knowledge of workplace hazards and the workplace safety controls that should be in place. You know the steps to take to assess hazards and put controls in place. This is a good time to update your Course Checklist.

You are now ready to move to Training Room 2: Workplace Safety in Action. You will create a pocket guide to workplace safety that you can take with you to your job site. Have fun with this. The pocket guide you create will be a real tool that might save you from injury while you work.