When a hazard has been identified, there are a series of pre-contact strategies that can be used to protect the worker from harm. These include the following:

If there is no choice for the worker but to be exposed to the hazard, then a worker can be required to use personal protective equipment (PPE) to manage the degree of risk.

In this session you will describe and demonstrate your understanding of the use of personal protective equipment to protect against a variety of hazards. As you work through the session, think about the following questions:

There are many different kinds of personal protective equipment for protection from different hazards.

Head Protection

Why protect your head?

Watch Put a Lid on Your Melon.

A helmet or hard hat should be replaced if it has been involved in a fall or been subjected to any other kind of impact, as it can become damaged and will no longer provide the protection it was designed for.

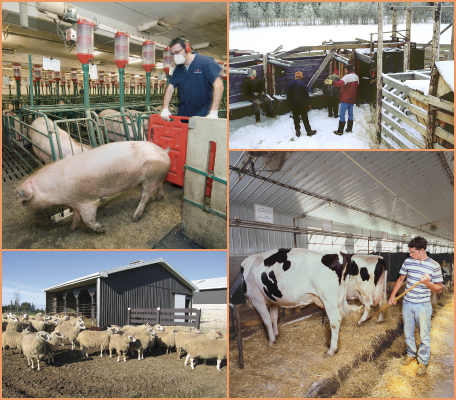

Courtesy of Sheila Ferguson and The Canadian Agricultural Safety Association

Courtesy of Sheila Ferguson and The Canadian Agricultural Safety Association Courtesy of Theresa Whalen and The Canadian Agricultural Safety Association

Courtesy of Theresa Whalen and The Canadian Agricultural Safety Association

Hard Hats: Wear a hard hat to protect your head from impact and penetration. Injury can occur when falling objects hit your head or if you bump into an obstruction. Read more about appropriate hard hat choice and care at Canadian Centre for Occupational Health and Safety—Care of Headware.

Helmets: Helmets are critical when riding moving vehicles, such as ATVs or motorbikes, or when riding horses or other livestock. Helmets protect the rider in two different ways, according to the Alberta Government's Safety Up—On Equestrian Helmets. First, they reduce penetration by sharp objects (the protective shell), and second, they absorb some of the force and give the head a cushion (the foam padding).

Read Safety Up—On Equestrian Helmets to learn more about the use and care of riding helments to prevent injury.

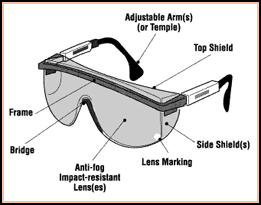

Eye Protection

Your vision is precious! Use PPE to keep your eyes safe.

Your eyes need to be protected from

- heavy dust particles (grain elevators, hay lofts)

- chemical splash or vapor (use of pesticides and fertilizers)

- flying debris (construction work, sanding)

- glare or intense light (welding or strong sunlight)

Eye protection can range from safety glasses, to goggles, to face shields, depending on the degree and type of hazard.

Use Eye and Face Protection eTool to determine what kind of PPE is best for the job at your worksite.

Claude LeBlanc, Courtesy of the New Brunswick Federation of Agriculture and the Canadian Agricultural Safety Association

Claude LeBlanc, Courtesy of the New Brunswick Federation of Agriculture and the Canadian Agricultural Safety Association

Hand Protection

© 2005 Workers Compensation Board of British Columbia.

© 2005 Workers Compensation Board of British Columbia.

All rights reserved. The skin of your hands is exposed to a variety of hazards that could include physical and chemical hazards. It is important to remember that gloves do break down and degrade over time and that some chemicals can seep through glove materials.

See the following chart for suggestions for gloves made of different kinds of protective materials for specific purposes.

What is an example of a guide to the selection of skin protection?

| Guide to the Selection of Skin Protection |

| Hazard |

Degree of Hazard |

Protective Material |

| abrasion |

Severe |

Reinforced heavy rubber, staple-reinforced heavy leather |

| Less Severe |

Rubber, plastic, leather, polyester, nylon, cotton |

| sharp edges |

Severe |

Metal mesh, staple-reinforced heavy leather,aramid-steel mesh |

| Less Severe |

Leather, terry cloth (aramid fiber) |

| Mild with delicate work |

Lightweight leather, polyester, nylon, cotton |

| chemicals and fluids |

Risk varies according to the chemical, its concentration, and time of contact among other factors. Refer to the manufacturer, or product MSDS. |

Dependant on chemical. Examples include: Natural rubber, neoprene, nitrile rubber, butyl rubber, PTFE (polytetrafluoroethylene),polyvinyl chloride, polyvinyl alcohol |

| cold |

|

Leather, insulated plastic or rubber, wool, cotton |

| heat |

High temperatures

(over 350 deg C) |

Asbestos, |

| Medium high

(up to 350 deg C) |

neoprene-coated asbestos, heat-resistant leather with linings |

| Warm

(up to 200 deg C) |

heat-resistant leather, terry cloth (aramid fiber) |

| Less warm (up to 100 deg C) |

Chrome-tanned leather, terry cloth |

| general duty |

|

Cotton, terry cloth, leather |

| product contamination |

|

Thin-film plastic, lightweight leather, cotton, polyester, nylon |

| radiation |

|

Lead-lined rubber, plastic or leather |

Respirator: Atmospheric Hazard Protection

Courtesy of the CCHSA and The Canadian Agricultural Safety Association

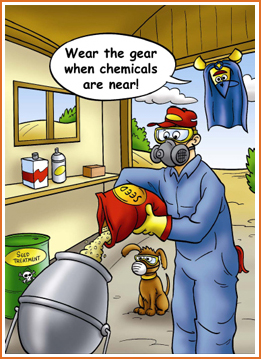

Courtesy of the CCHSA and The Canadian Agricultural Safety Association Respirators can be used when all other controls have been considered for the hazardous contaminants in the air. Use of less hazardous materials and proper ventilation should be implemented if possible.

Courtesy of the FARSHA and The Canadian Agricultural Safety Association

Courtesy of the FARSHA and The Canadian Agricultural Safety Association Alberta Agriculture and Rural Development describes these particular hazardous environments as ones needing respirators:

- working in dusty buildings or fields

- entering silos or manure pits

- handling mouldy hay

- applying pesticides or fertilizers

Watch Using Pesticides Safely from Alberta's Farm Safety: It's No Accident to learn about respirator use with pesticides.

Air Purifying Respirators: These are used to clean contaminants from the air when there is enough oxygen to sustain life. Some air contaminants require chemical cartridge respirators or gas masks so that the air is properly cleaned.

Atmosphere Supplying Respirators: These are required when there is not sufficient oxygen, such as in manure pits or silos. Use of these requires special training.

Read more about the different kinds of respirators on this site. Link: Respiratory Protection for Producers from Alberta Agriculture and Rural Development.

Alberta Farm Safety. Used with permission. |

Alberta Farm Safety. Used with permission. |

Air Purifying Respirators: Disposable Dust Mask

From Alberta Government's Respiratory Protection for Producers |

Air Purifying Respirators: Multi Use Dust and Mist Mask

From Alberta Government's Respiratory Protection for Producers |

Foot Protection

Steel toed work boots and shoes with non-slip soles are critical to protect feet from injury and prevent falls in the workplace. Agricultural workers who are on their feet for much of their working day also need to ensure proper fitting footwear to reduce fatigue and sore feet.

How Is Footwear Selected?

According to an article by The Canadian Center for Occupational Health and Safety—Safety Footwear, footwear must be chosen based on the hazards that are present.

They suggest assessing the workplace and work activities for

- materials handled or used by the worker

- risk of objects falling onto or striking the feet

- any material or equipment that might roll over the feet

- any sharp or pointed objects that might cut the top of the feet

- objects that may penetrate the bottom or side of the foot

- possible exposure to corrosive or irritating substances

- possible explosive atmospheres including the risk of static electrical discharges

- risk of damage to sensitive electronic components or equipment due to the discharge of static electricity

- risk of coming into contact with energized conductors of low to moderate voltage (e.g., 220 volts or less)

Also, evaluate the risk

- to ankles from uneven walking surfaces or rough terrain

- of foot injury due to exposure to extreme hot or cold

- of slips and falls on slippery walking surfaces

- of exposure to water or other liquids that may penetrate the footwear causing damage to the foot and the footwear

- of exposure to rotating or abrasive machinery (e.g., chainsaws or grinders)

Courtesy of the University of Minnesota Extension and The Canadian Agricultural Safety Association

Courtesy of the University of Minnesota Extension and The Canadian Agricultural Safety Association Go to The Canadian Center for Occupational Health and Safety—Safety Footwear to see the symbols or markings on footwear that help you determine what kinds are needed for specific jobs.

Hearing Protection

Courtesy of The Canadian Agricultural Safety Association

Courtesy of The Canadian Agricultural Safety Association Why is hearing protection especially important to farmers? According to Alberta Agriculture and Rural Development, "farmers use many different types of machinery that produce excessive amounts of noise, including tractors, grain dryers, and radios in enclosed cab tractors. Swine barns at feeding time contain extremely high noise levels. In addition, farmers are around these high noise levels for long periods of time, thus making the risk of hearing loss even greater."

Hearing loss can be prevented by use of disposable earplugs easily purchased at drugstores or by use of ear muff style hearing protection.

Watch The Hearing Video, produced by WorkSafe BC, for fun and informative information about hearing and about choosing the correct PPE to protect yourself.